What is SNG?

Synthetic Natural Gas (SNG, also called Syngas at times) is a mixture of air and Liquefied Petroleum Gas (LPG). Typically, the ratio of air and LPG used in a conventional SNG system will depend on several factors, e.g. available LPG blends in the market, location altitude and climate, and, most importantly, the application for which SNG is to be used.

LPG & its Blends:

LPG, as most people would know, is a member of the fossilized fuels family, a mixture of hydrocarbon gases (essentially Propane and Butane), and usually derived during the refining of crude oil, or extracted from oil or natural gas streams (refining ‘wet’ natural gas) as they emerge from the ground. Propane and Butane are usually mixed in desired ratios to form the required ‘blend’ of LPG for specific applications.

SNG:

Synthetic Natural Gas is an ideal replacement fuel for Natural Gas, which is the primary fuel used by the industrial and commercial sectors because of the low cost and environmental benefits as compared with conventional fossil fuels (e.g. diesel, petrol, furnace oil). However, with rapidly diminishing natural gas reserves, and consequent constraint on supplies, the government has had to ration NG usage and it is commonly commented that restrictions will only become stricter during the upcoming winter months and following years.

LPG is an ideal alternative fuel for NatGas applications (as SNG) as well as for vehicles (petrol engines have been run on LPG “autogas” the world over for decades). LPG, when mixed with air under controlled conditions, can acquire the burning characteristics of NatGas (the ‘Wobbe’ index) thus allowing users to utilize existing NatGas power generation sets, burners, piping infrastructure and so on. There is generally no need to change the setup of the combustion equipment when the fuel supply changes from NatGas to SNG or vice versa.

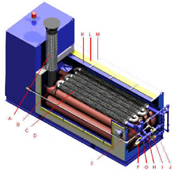

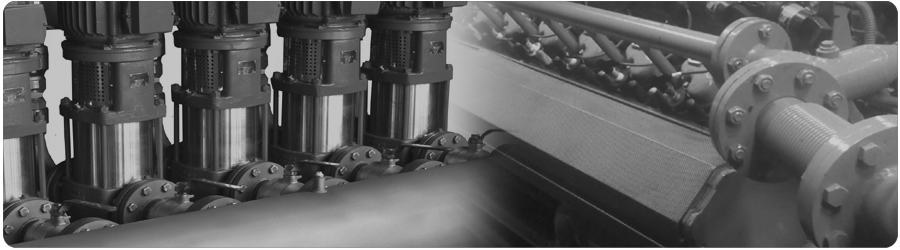

With top-of-the-line systems and industry leading experts, AES and Vensol offer a full range of services and customization to tailor the system to your specific requirements.

APPLICATIONS:

The greatest strength of LPG-Air Mix (SNG) lies in the diversity of applications it offers. To list the main ones:

- SNG operates your NatGas Generators with ease and efficiency just as if they run on NatGas. Hence, no heavy capex requirements in the form of purchasing different/new equipment for power generation.

- It is used to fire almost any Furnace (with AES equipment being a highly favoured brand by Float Glass plants because it offers “continued production” and not just “asset protection”, which only keeps the kilns warm to maintain the liquid line temperatures).

- Most Boilers can be run on SNG to produce steam for processing or other requirements (e.g. chillers dependent on steam production).

- Piped SNG – where no NG is available, or like to be made available, for existing communities or new Housing Developments, SNG is supplied through pipeline networks to fill the cooking and/or heating needs of the population. Such projects are in abundance around the world, with China now cited as one of the fastest growing user of these systems.

THE NEXT STEP?? SIMPLY DOWNLOAD THE BRIEF QUESTIONNAIRE (IN THE DOWNLOADS SECTION), FILL THIS IN TO REFLECT YOUR CONSUMPTION & REQUIREMENTS, AND EMAIL OR FAX TO US. WE WILL REVERT WITH A CONFIGURATION AND PRICE PROPOSAL ON THE MOST SUITABLE SYSTEM FOR YOU WITHIN A FEW WORKING DAYS!